1.introduce

Axial-flow pump belongs to vane-type pump as well as centrifugal pump and mixed-flow pump, but theirworking principle is different.The axial-flowpump use the thrust generated by the rotating vane to make theliquid flowalongthe pumpaxis.

The flow range of the axial-flow pump is very large, generally from 150m3/h36-3.6 million m3/h,and the head is below 7 meters. Specific speed ofaxial-flowpump is between 500to1600which is the highest in vane pump. According to the installation style, axial-flow pump can be divided into vertical, horizontal, oblique and through-flowtype.

The impeller of the pump has two different type. One is fixed usually using in small capacity pump. other is adjustable type, when the operating condition (mainly referring to the flow rate) need to be changed, you can adjust the setting angle tokeeping the pumprunning on the high efficiencylevel.

It should be avoided to starting pump in small flow rate because the flow-head, flow-shaft power curve is steep in this area. The shaft power of axial-flow pump is the maximum at zero flow, so the pump needs to start before openvalve.

Commonly the pump used in industry wastewater treatment, sewage treatment,paper and pulp industry, chemical industry and petrochemical industry, salt, alkali and power plant circulating water pump and other industry, especially widely used in environmental protection, vacuum salt production, high saltsewage, paperevaporation sectionandotherindustry.

2.parameter

Capacity:Q<25000m3/h Head:H<7m.

Pipe diameter:DN150-1500mm Temperature:-40-160 oC.

Max operating pressure:0.6MPa.

3.Structural features

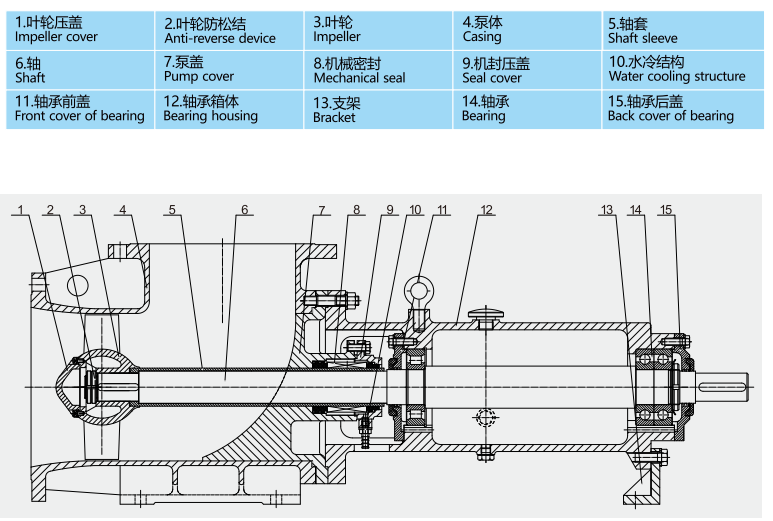

1.YZW axial-flow pump is a single-stage radial section type, which can be designed reasonably and disassembled conveniently. According to the different casing, it can be divided into two kinds of structures: bend pipe type and volute type. According to different installation forms, it can be divided into horizontal and suspension.According to different connection modes, it can be divided into three forms: direct connection, reducer connection and belt connection.

2.The rotation direction of the pump: the elbow type can be determinded by the user's condition, so the rotation direction is uncertain.

3.Vane type

(1)Fixed vane-vane settling angle is fixed. When the working condition changes, the impeller needs to be replaced.

(2) Semi-adjustable vanes-it can adjust settling angle by removing the impeller when the pump stops for varying operating condition. This can improve the efficiency of the unit and save energy.

4.Bearing Unit

The bearing parts including the shaft are calculated accurately, and their strength and rigidity can meet the requirements of the power parameters in the maximum condition with reasonable cost and quality.

5.Mechanical seal or packing seal can be chosen according to the type of the transport medium.

6. For easy to maintain, it adopts rear door structure which can pull out the whole rotor without dismantling the inlet and outlet pipeline.

WeChat

WeChat