1.introduce

YCZ process pump is a Horizontal single-stage single suction centrifugal pump; its conforms to DIN24256/ISO2858 standard.

YCZ pump can transport low or high temperature liquid; neutral or corrosive liquid, clean or containing solid particles of liquid, can be widely used with chemical industry, chemical fertilizer, petroleum, metallurgy, power, paper, food, pharmaceutical, alloy fiber and other industrial sectors.ction, vacuum salt production, high salt sewage, paper evaporation section and other industry.

2.parameter

Capacity:6.3-2000m3/h Head:5-160m.

Temperature:-80-300 oC.

Max operating pressure:1.6MPa.

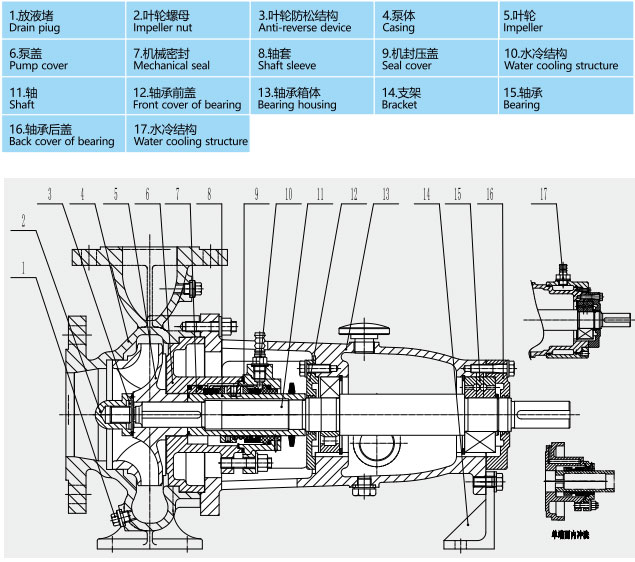

3.Structural features

The external installation dimension and base are designed in accordance with international standards, which can replace the imported pump

The inlet and outlet of the pump are on the same axis, which is convenient for design and process connection

Bearing frame, including shaft, impeller, packing culvert and so on, forms an assembly, so that the pump body does not need to be removed from the pipeline during maintenance, so the extended coupling is adopted, and the motor does not need to be removed.

The pressure acting on the shaft seal is compensated by the auxiliary impeller or the balance hole on the impeller. The shaft seal can be sealed with soft packing (it can be cooled or not), or it can be sealed with single or double face machine seal of various structures.

The ball bearing is durable and the shaft diameter is abundant to ensure the running balance

Horizontal back door opening structure, the pump head and motor are connected by coupling, installed on the bottom plate, the impeller is back open, three bearings, the shaft seal is external mechanical seal, equipped with cooling device, the oil level of bearing body is observed by oil mirror; the structure is compact and reasonable. The pump has feet cast on the pump body, which can bear the load from the pipeline and directly transmit it to the foundation, so that the pump rotor will not be bent due to the load borne by the pump, thus ensuring the good service life of the bearing and mechanical seal. During maintenance, it is not necessary to open the pipeline conrected with the pump body. As long as the bolts of bracket and pump body are opened, the impeller and mechanical seal can be maintained by separating the two, which is simple and convenient.

WeChat

WeChat